When it comes to making leather hats, it's good to come to the source. Since 1972, the American Hat Makers has been handcrafting the world's finest hats, and these are our secrets.

How to Make a Leather Hat Step-by-Step

Step 1 - Hat Making Supplies

Start with the best materials and supplies. It doesn't matter how good your handiwork is if your materials need to stand up to the test of time.

Our leather hats start as a hide of heavyweight top grain leather, which is cut into our hat parts using industrial hydraulic presses.

Step 2 - Parts of Hats and Cutting Leather

Cut out your hat parts from the hide. All of our hat parts are cut out using pre-shaped dies that make up the three basic parts of the hat.

The brim, the crown, and the top. At this phase of production, we cut out two of those shapes, the brim, and the crown. We'll get to the top of the hat here in a bit!

For this specific tutorial, we're gonna be making one of our iconic leather outback hats, so the brim will be wider than some of our other hats.

Step 3 - Hat Crown

Next, we start building the basic crown shape. The crown we punched out is one solid piece of leather, but it needs to be formed into a shape that will fit around someone's head.

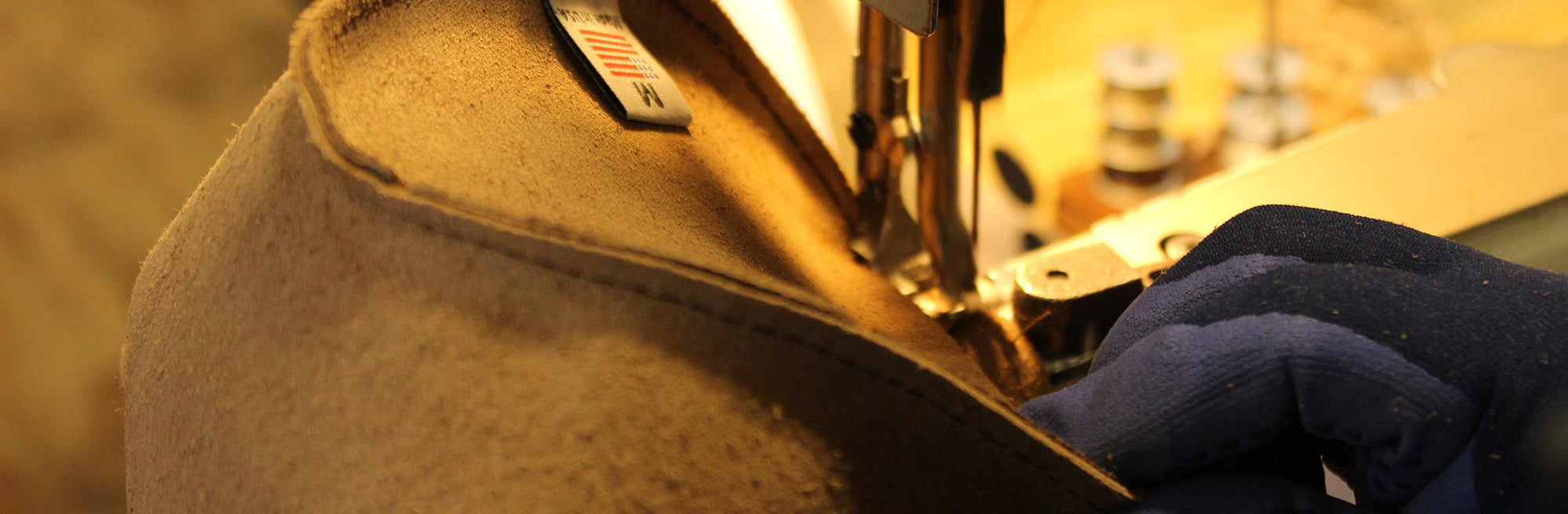

To do this, we fold the crown into a circle and stitch it from the inside out. All of our leather hats are built inside out and then flipped so all of the stitching is protected on the inside of the hat.

Once this crown is all sewn up, we need to top it off.

Step 4 - Hat Brim

Finish the brim, and top of the hat. To get the top of the hat, we take the brim and punch out a hole in the middle, meaning that the leather piece we create is a perfect match to be the top of the hat.

We then take this piece and sew it onto the crown. Before moving on to the next phase, we sew on the tags and velcro buttons that hold our replaceable sweatliners in place!

Step 5 - Finishing Touch

Finishing touches. At this stage, the hat is flipped right side out, and the brim is sewn on.

Finally, this top grain leather hat has the sweat liners added, and is conditioned and shaped before going to our shipping department so it can be shipped off to it's lucky new owner!

Step 6 - Final Product

How did your final product come out? Take it for a test drive and wear it somewhere fitting! Congrats!

You're the newest addition to the American Hat Maker company family! Time to hit the trail and show off your new leather hat!

How to Make a Leather Top Hat

The El Dorado leather top hat is our best selling leather top hat and it was an obvious pick for one of our "how to make a leather hat" choices.

The El Dorado Top Hat is a master at transformation being the base hat for so many other popular favorites and different styles in our top hat community.

You can catch it on the red carpet, flying by you at a biker rally, bobbing along through the crowd at a music festival or in the street as some ones daily hat.

How to Make an Outback Hat

The Crusher Leather outback hat, let's talk about this beast of an indestructible hat. It has a tasseled braided leather hat band and matching stampede string comes in many different colors and styles.

This lightweight all-weather Aussie style outback/cowboy hat has a flat crown, wide brim for weather and sun protection as well.

Pack it, crush it, throw it in the truck or a bag...it's still wearable.

How to Make a Cowboy Hat

Another one of our favorites is the the Cyclone Leather cowboy hat. The leather used for these are different throughout some of the colors because we have chosen only the best quality leather for each color we carry.

The texture on these are a masterpiece in itself. You know those really comfy leather chairs you see in a high-end executive office that feel like a cloud when you sit in it, that's how the Cyclone feels when you put it on.

Comments

I need cowhide leather hat : 1pic

Wow, what a great blog.